Cleaning Coal – Callide, Clinkers and Calamity

An explosion at Callide C... no, not that one, another one

A huge thank you to Andrew J. for his help reviewing this article. And shoutout to mum who put me on to this story in the first place!

In case you completely missed it, like I did, in early April the *ahem* troubled CS Energy Callide C plant experienced what the company described as a “pressure spike” and what the Mining and Energy Union described as an “explosion”.

Firstly, yikes. Secondly, no notes. That is the most perfect example of diverging descriptions you could get from a plant owner and a union.

Let’s dive into what happened, and the political aftermath. Also, this one is a loooong one. Grab a cuppa.

Boil the jug, wouldya

If I can be extremely reductive (understatement), coal-fired stations are just big, extremely complicated kettles. Cold (well, ambient) water goes in, is heated up until it’s boiling, and then pushed as steam through a turbine. The enthalpy1 of the steam is used to spin a turbine, which generates electricity via the generator. The steam exiting the turbine is then cooled back to ambient and fed back into the boiler, starting anew.

As discussed previously, the coal which is burnt can be of varying grades, which has a significant impact on the design of the boiler (as well as some of the balance of plant). A general rule in Australia is that Queensland and New South Wales plant are all powered by black coal (bituminous or sub-bituminous), Victorian plant on brown coal (lignite) and the best stuff is exported to keep Australia’s insatiable financial services industry fueled.

The slightly less reductive description of a coal-fired power station is that they operate based on the Rankine cycle, which is the formal engineering name for the heating and expansion of the water into steam and condensation back into water. The power output (or work) from a Rankine cycle is directly proportional to the temperature difference between the hot steam entering the turbine and cold water exiting it.

Over the last century there have been significant developments figuring out how to best use water and heat to extract the most amount of energy possible out of the Rankine cycle, leading to larger and more powerful turbines.

The majority of existing coal-fired power stations in Australia use the Rankine cycle with reheat – steam leaves the boiler and goes into the high pressure turbine, and then enters back into the boiler to be heated again (in the imaginatively named reheater circuit) before entering the intermediate and low pressure turbines to extract as much remaining energy as possible.

The steam is ‘superheated’ in these plants to ensure that it is dry when leaving the turbine2; but otherwise follows how you might imagine a big complicated kettle works – water is heated until it is completely boiled into steam and then you do something useful with it.

Not quite a gas, not quite a liquid

There is however another phase, sort of, which water can take. If take water at sufficiently high pressure and heat it up, it skips the gas phase (steam) entirely and becomes a supercritical fluid.

The properties of this supercritical fluid can be taken advantage of to squeeze out a higher efficiency from the turbine – the temperature is more efficiently converted into mechanical energy.

Philo Unit 6 in Muskingum County (God, what a name), Ohio was the first commercial supercritical plant, operating in 1957. However supercritical designs didn’t really take off until the later part of the twentieth century – advanced materials (exotic alloy steels and exotic stainless steels) are required to operate at such high temperatures and pressures.

The supercritical Rankine cycle with reheat is shown in the diagram below — note the missing upper isotherm, the water just skips straight past the critical point.

The conventional design of coal-fired boilers – where the water is boiled (in the first T-s diagram above the water goes ‘through the bell’) – are referred to as subcritical units, and the units where supercritical steam is used – you won’t believe this — are called supercritical units.

There are only four supercritical units in Australia – Callide C, Millmerran, Tarong North and Kogan Creek – all located in Queensland and commissioned between 2001 and 2007.

It’s worth pointing out here that you’ll sometimes see supercritical and ultrasupercritical3 units referred to “High Efficiency Low Emissions” or HELE plant. This is little more than a marketing term, not dissimilar to the entire concept of “clean coal”.

Biloela

Callide C is one of these supercritical units in Biloela Queensland. It was commissioned in 2001, next door to the existing subcritical Callide B station commissioned in 1988 and Callide A commissioned 1965-1969, mothballed in 2002 and permanently decommissioned in 20164.

Callide B has two 350 MW turbines, and the two Callide C units are known as C3 and C4 – each 405 MW when installed, but since upgraded to ~460 MW each.

Although all of the Callide units are operated by the Queensland Government-owned CS Energy (which also owns Kogan Creek amongst other generation assets), only Callide B is wholly owned by CS Energy, whereas C station is owned in 50/50 joint venture between CS Energy and IG Power.

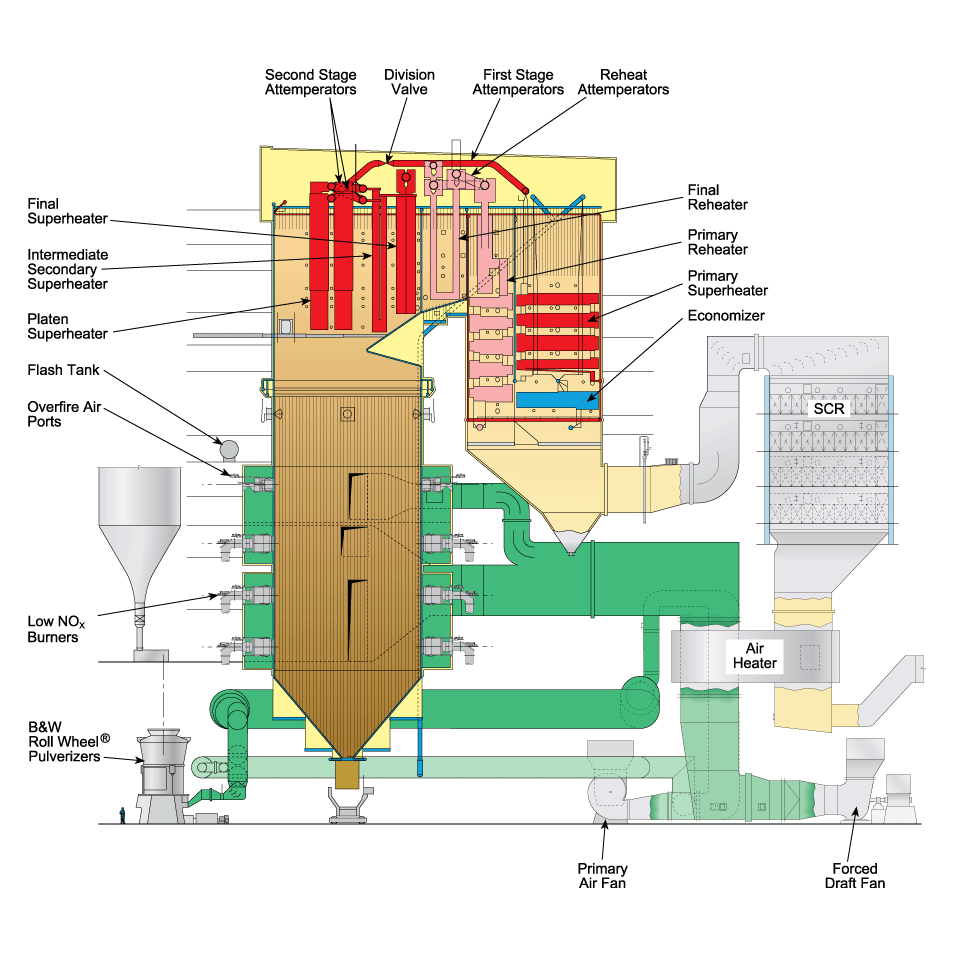

The Callide C boilers5 were built by the Japanese company IHI Corporation, and I can’t find a precise diagram, but the design is close enough to the Babcock & Wilcox spiral wound universal pressure boiler utilised at Millmerran6 (which is similar in size and age), which I do have a diagram for7.

Firing the kettle

Ok – bear with me. I’ve talked about the some of the theory, let’s talk now about how it comes together.

Coal is mined from the nearby Callide Coalfield and transported via a long conveyor belt to a stockpile which feeds both B and C station.

In order to be burned, the coal is fed into pulverisers (aka mills), and ground into small particles (a fine coal dust – think talcum powder). This coal dust is then combined with air and sent to the burners, which create a literal giant fireball inside of the 10 storey high boiler – the inverted brown milk carton on the left in the diagram above.

The wall of the boiler is made of waterwall tubes, which carry the water to be heated. The heat transfer from the fireball to the water inside of the tubes both heats the water, and keeps the steel tubes below their melting point.

Now, like most mined ores, coal is not 100% coal8 – there are a range of other minerals also dug up with the coal, some of which do not combust. These ‘coal combustion residuals’9 are referred to as coal ash.

The smaller, lighter particles of ash, known as fly ash, are transported through the furnace and are caught in the baghouse (which is a fancy filtration system) before the chimney. The larger, heavier particles – bottom ash – fall from the fireball down into the ash handling system at the bottom of the boiler.

If the chemistry is right, most of the heavier ash melts and sticks to itself and then either sticks to the boiler walls, like toffee to an apple, or falls to its watery escape.

Callide C has a ‘submerged chain conveyor’10 at the bottom of the boiler – high temperature ash falls to the bottom of the boiler where it has a nice cooling bath in the water, before being taken on an excursion out of the boiler via the chain conveyor.

This sticky toffee ash which forms on the walls and tubes inside the boiler (including the hanging platens – the superheater and reheater tubes) is referred to as boiler slagging or clinker.

All boilers have active management systems for dealing with clinker – the three primary ones are:

Soot blowers which typically shoot high pressure steam, like a giant Gerni.

Water lances which are effectively giant supersoakers shooting across the furnace to the opposite side, trying to dislodge tenacious clinker. These are deliberately targeted at sections of the waterwall with low heat flux (where clinker is affecting the heat transfer capabilities of the waterwall).

Clinker de-loading cycles where the unit is ramped down to a lower power output and the change in temperature (and resulting shrinkage) of the waterwall tubes mechanically shocks the clinker off.

In extreme cases excessive buildup of clinker can also be dealt with via an outage – shutting the unit down and going in to clean it out. This is obviously an undesirable option.

Why do we care about clinker? For one it forms a thermal barrier and reduces heat transfer, which could cause overheating of the underlying steel tubes. For two that sticky melted ash forms increasingly larger chunks of clinker, and unmanaged clinker deposits can grow to terrifying sizes. In extreme cases clinkers the size of a mini bus can form, and eventually drop, blowing the arse out of the boiler like a Taco Bell enchilada with extra cheese.

An explosive pressure spike

Ok, we got here, finally. Let’s talk about the incident at Callide C3 on April 3. The following timeline is pieced together from AEMO MMS data in conjunction with CS Energy’s press release from 10 April.

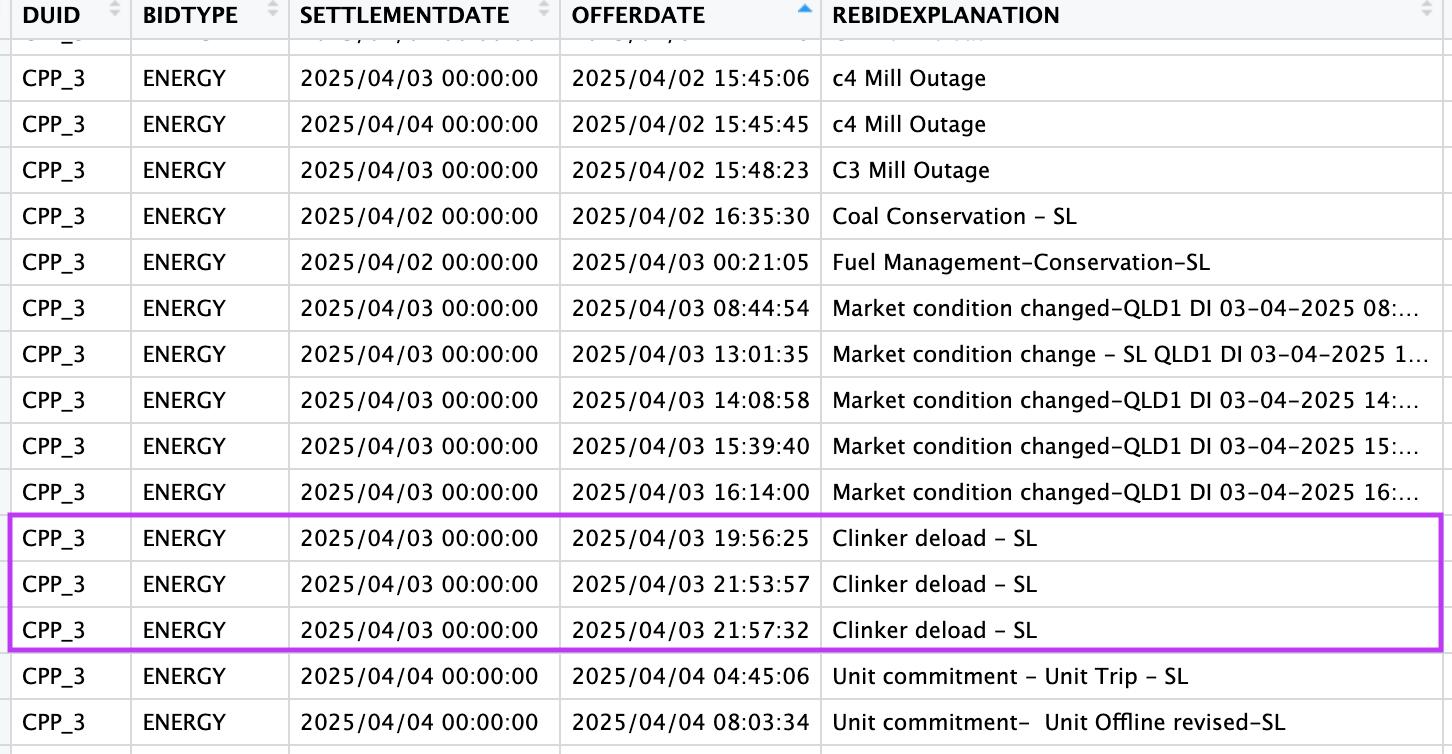

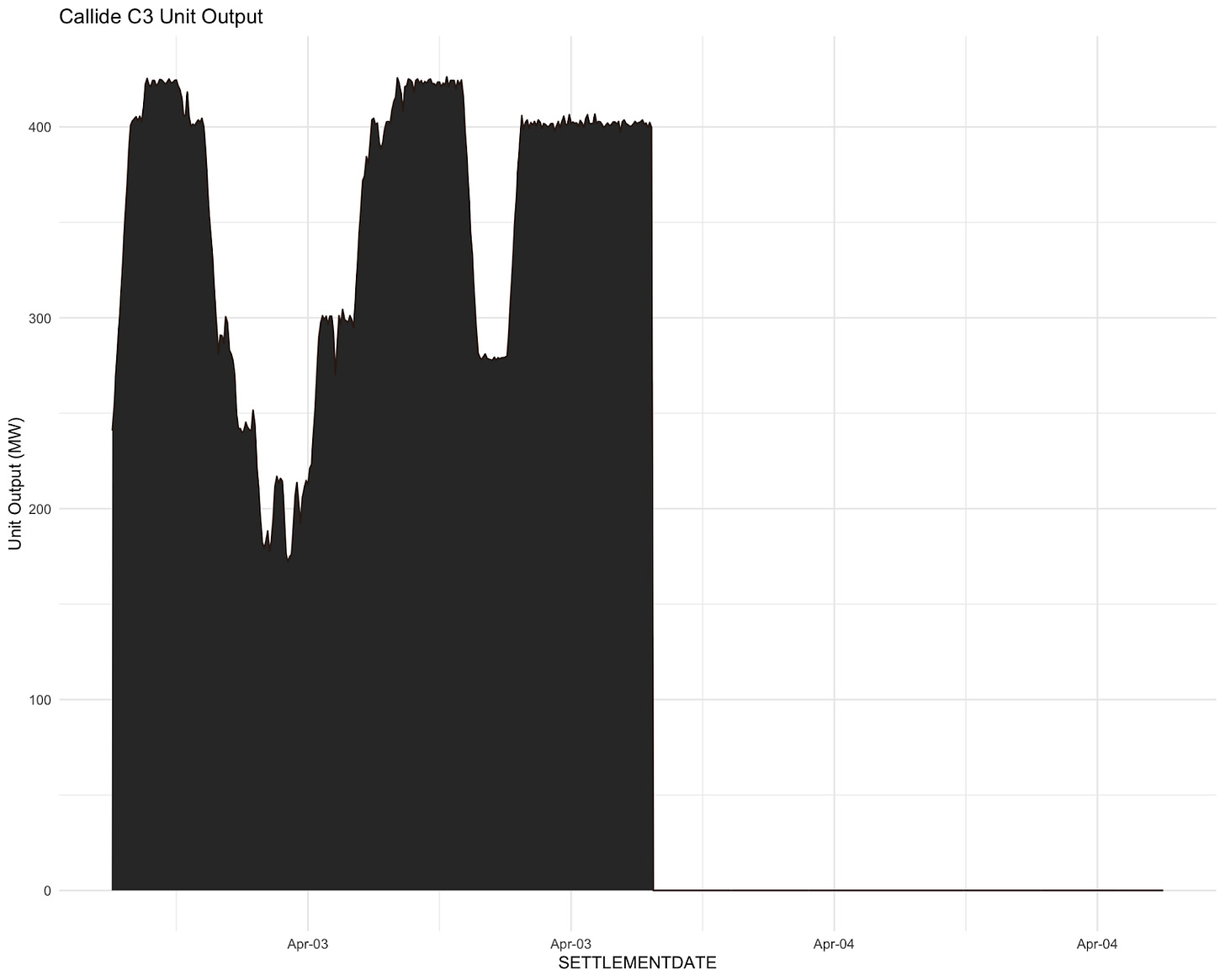

On 3 April around 8pm, the operators initiated the daily clinker deloading cycle and ramped unit C3 from 424 MW down to 280 MW. We know this was a clinker deloading cycle (as distinct from an economic ramp down) based on the unit rebids11.

The operators originally planned to do a deload cycle between 20:00 - 22:00 (the first rebid at 19:56), but just before 22:00 extended the cycle to 22:30 (second rebid at 21:53), but then 4 minutes later decided that wasn’t needed (third rebid at 21:57) and reverted to the original schedule of returning to full load at 22:00.

Nearly 7 hours later, between 04:40 and 04:45 on Friday 4 April a big ol’ lump of clinker detached itself from the wall and fell into the bottom of the ash conveyor. This extremely hot lump of ash12 immediately superheated (flashed) the water in the submerged chain conveyor to steam.

This giant plume of steam shot upwards and extinguished all four burner flames – leading to an automatic unit trip as part of the safety design.

According to CS Energy:

The flame loss led to furnace pressure fluctuations—initially negative as the collapsing flame drew in unburnt fuel and air, followed by a positive pressure surge caused by the re-ignition of the accumulated fuel and the subsequent gas expansion. This pressure event dislodged insulation and cladding materials from the boiler walls, causing damage to adjacent platforms. Importantly, there was no loss of high-pressure steam or water.

At this point it was well and truly lights out for the unit — operators rebid the unit to indicate the failure (and probably also called the AEMO control room directly). At 8am operators revised their bids to indicate that the unit was gonna be offline for a good while, as well as (later) updating the longer term MT PASA bids to indicate that the unit would be offline until the end of May (56 days).

Given the long outage – nearly two months – CS Energy’s statement that the “pressure event dislodged insulation and cladding materials from the boiler walls, causing damage to adjacent platforms” seems rather understated. The “adjacent platforms” is likely the most important part of that sentence. It would not be shocking if the boiler buck stays – external structural beams which stiffen the outside of the boiler walls – might be bent. That would explain a two month outage, not merely dislodged cladding.

But what happened next is where this story gets juicy.

A bad start to April

Let’s recap what was a bad couple of weeks for CS Energy and Queensland’s new energy minister:

On Thursday 3 April the CEO of CS Energy, Darren Busine tenders his resignation, wrapping up in early May. However this wasn’t publicly announced until later in the week.

On Friday 4 April unit C3 suffered the *ahem* ‘pressure spike’.

On Tuesday 8 April Queensland’s Treasurer, Minister for Energy and Minister for Home Ownership13, David Janetzki gives a keynote speech at the Queensland Energy Club, and amongst other things — including cuts to the previous Labor government’s renewable plans — announces that Callide B will be extended several years beyond the current retirement date of 2028.

Also on 8 April the resignation of CS Energy’s CEO is formally announced.

On Wednesday 9 April The Australian publishes an exclusive article about the explosion.

Also Wednesday 9 April – CS Energy releases the first public statement about the incident (outside of rebid and unit output data from MMS).

On Thursday 10 April CS Energy releases more detail on the explosion. It’s probably not related to The Oz article…

On Monday 14 April the CEO — the one who’s already tendered his resignation — is asked to step aside immediately, as well as the Callide station manager. Heads have officially rolled.

On Wednesday 16 April CS Energy releases a short ‘sorry we’ve been naughty Minister’ press release referring to ‘cultural issues’ and introducing ‘real-time outage reporting’. Yikes.

This is an objectively funny sequence of events that could have been a Yes Minister plot — power plant suffers an explosion pressure spike the week before the new Minister makes his first big political announcement unwinding some of the previous government’s work and extending the life of the station next door, a major newspaper breaks an exclusive story, the Minister is embarrassed and does what Ministers do — rolls some heads (and forces them to write a public apology note).

Whether the Minister was actually kept in the dark or just failed to appreciate the significance of the issues until the media pressure mounted is unclear:

Janetzki accused state-owned CS Energy of failing “to communicate the seriousness of the incident” on April 4, despite admitting to being briefed on the situation.

Just days before, Mr Janetzki had said he was briefed on what happened and that it was “publicly available information”.

The story is still evolving — the day prior to publishing, Monday 19 May, CS Energy released an update announcing that C3 will be offline for a couple days longer while they undertake some pre-emptive maintenance on cracking in the high pressure steam piping. The cracking is unrelated to the clinker fall — CS Energy is just taking advantage of doing some additional work while the unit is offline.

And then this bit lower down in the press release:

Work is continuing to repair the areas of Unit C3 damaged in the major operational safety event on 4 April 2025. Approximately 100 people are working on rotating shifts six days a week, with approximately 25,000 hours worked since the project began.

Yeah… 25,000 manhours speaks to the seriousness of this ‘major operational safety event’.

A series of unfortunate events

Whatever the truth, this is an unfortunate addition to the list of major incidents which Callide C has racked up in recent times. For those playing along:

In May 2021 Callide C4 (literally) blew up a turbine, blacking out a big chunk of Queensland and taking over 3 years and maaaaany millions of dollars to return to service.

In October 2022 one of the cooling towers at Callide C3 suffered a structural failure, taking the unit offline for 18 months (and costing slightly less millions of dollars).

In 2024 CS Energy finally released the Brady report summarising of the findings on the 2021 C4 incident by forensic consulting engineer Dr Sean Brady. The report is damning, to say the least, detailing major cultural issues within CS Energy (CS Energy fought Sev.en bitterly in court to prevent its public release).

And on 5 February 2025 the AER (finally) issued a massive14 fine for the 2021 C4 incident, levying a penalty of $9 million out of a maximum $10 million against CS Energy.

And that’s not to mention the brewing spicy court battle, in which Sev.en will likely lean on things like the Brady report to allege mismanagement of the plant by CS Energy and go after them for more money.

So while the new Queensland government seems keen on keeping B station open for longer, maybe they should just call it quits on C station. No one needs to see what happens if you order extra cheese.

A fancy thermodynamics term for measuring the energy of a system.

Saturated steam – steam containing water droplets is extremely bad for turbine blades.

More modern units with ever higher temperatures and pressures, and super exotic materials to handle those temperatures and pressures.

Callide A was brought out of storage, refurbished, and retrofitted with oxyfuel technology. The project was a technical success — they demonstrated carbon capture — but describing the project as “[leaving] an exciting legacy for low emissions future clean energy innovation” is a nice corporate way of saying it was a fucking boondoggle.

Technically supercritical water doesn’t boil, so can you call them boilers? Anyway.

If you like joining dots, Millmerran is owned and operated by InterGen — where the IG bit of IG Power comes from. InterGen was purchased by Sev.en a couple years ago, the Czech private equity firm specialising in “ESG-deprived assets”. Sev.en also own Delta’s Vales Point power plant in NSW (which we wrote about last year). Oh yeah, also Sev.en and CS Energy are caught in a protracted legal fight over the 2021 C4 explosion (the other explosion).

B&W’s marketing material is much better than IHI’s, so this is what we’re running with. Also I think ‘spiral wound universal pressure’ boiler is a B&W trademark; look at me falling victim to the coal industry’s marketing.

And in the cases where it is, that’s the good shit which we export for princely sums.

A descriptive if deeply unsexy term.

Please enjoy this excellent promotional PDF of a submerged chain conveyor. Don’t thank me, thank the fine folks at Babcock and Wilcox.

SL is short for see logs, a common shorthand operators use in rebids to indicate that the AER or AEMO can seek additional information if required (without having to reveal more information to the market or competitors).

There is no specific information on the clinker, but it wouldn’t be unreasonable to suspect that it formed at the transition from the waterwall to the hearth sloped walls. When the clinker finally let go, betwen a hundred and two tonnes of gravel-like material would have made its way to the SCC. High surface area = high steam generation.

What a wild confluence of portfolios.

I just wrote massive, but it’s worth putting in context that if Callide C3 operated at full output they could could make that much in wholesale revenue in under a fortnight. This is a severe oversimplification of the dispatch dynamics, but still, $9 million is chump change in the scheme of energy markets.

On a tour of one of the NSW coal fired power stations, one of the operators told me they'd sometimes tackle stubborn clinker with a shotgun

Okay, serious then: to what extent was this largely a "cultural" (read management) problem, which should be relatively easy to fix or in fact a technical/mechanical/structural problem with the units themselves, which might well justify closure.

Given that they're coalers, I wouldn't be upset if it was the latter.